Material testing

MTM STAL company, located in Tarnowskie Góry, offers comprehensive alloys metal testing. Among the offered services, you can find chemical composition analysis and mechanical properties characteristics.

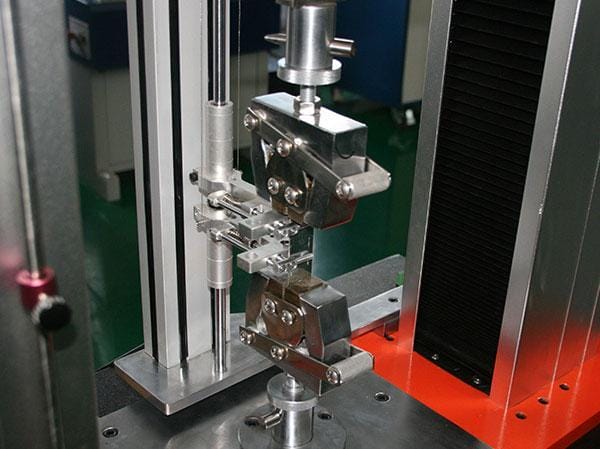

Tension testing

Tension testing involves endurance analysis. We test the stretching, compression, distorting, and stretching joint elements. There is a chance to do a survey in different environments (fluid, gaseous) and also in different temperatures (raised and reduced).

Non-destructive testing (NDT)

Non-destructive testing allows us to detect the material abruptions and to assess physical material features. Surveys concern domestic abruptions, surface and subsurface abruptions.

Thanks to that, there is a possibility to detect craquelures, aerification, and scratches of a product. We offer non-destructive testing: visual, radiographic, ultrasonic, and others.

Metallography testing

Metallography testing allows determining initially the mechanic metal features. We do the surveys in two ways: macroscopic and microscopic. We choose the method according to the individual client's needs. The survey results allow us to exposure exploitative or environmental changes, but also to observe the material surface.

Chemical composition testing

We provide the services in terms of chemical analysis of alloys' technological metal composition. We provide high-tech analysis techniques susceptible of reliable chemical composition control. We provide the material analysis of copper, brass, bronze, zinc, aluminum, iron, and steel.

If you have any questions – we are on call.

- tension testing

- NDT

- metallography testing

- chemical compositions testing